Harmony International’s Advanced Injection Moulding Solutions

Embark on a journey of innovation and flawless execution. Our state-of-the-art injection moulding facility, driven by cutting-edge technology and fueled by expertise, is your gateway to turning ideas into reality. Backed by a robust capacity and an unwavering commitment to quality, Harmony International sets the stage for unparalleled precision in every mould. Your possibilities are limitless; let’s shape them together.

Exceptional Craftsmanship

Experience unparalleled craftsmanship with our dedicated team, ensuring every leather garment or injection-moulded product reaches the pinnacle of quality and precision. Choose us for industry-leading expertise and artistry.

Customer-Centric Approach

We prioritize transparency and reliability, placing your satisfaction at the heart of our operations. With timely deliveries and unwavering quality, your success and peace of mind are our top priorities. Choose us for a dependable partnership you can count on.

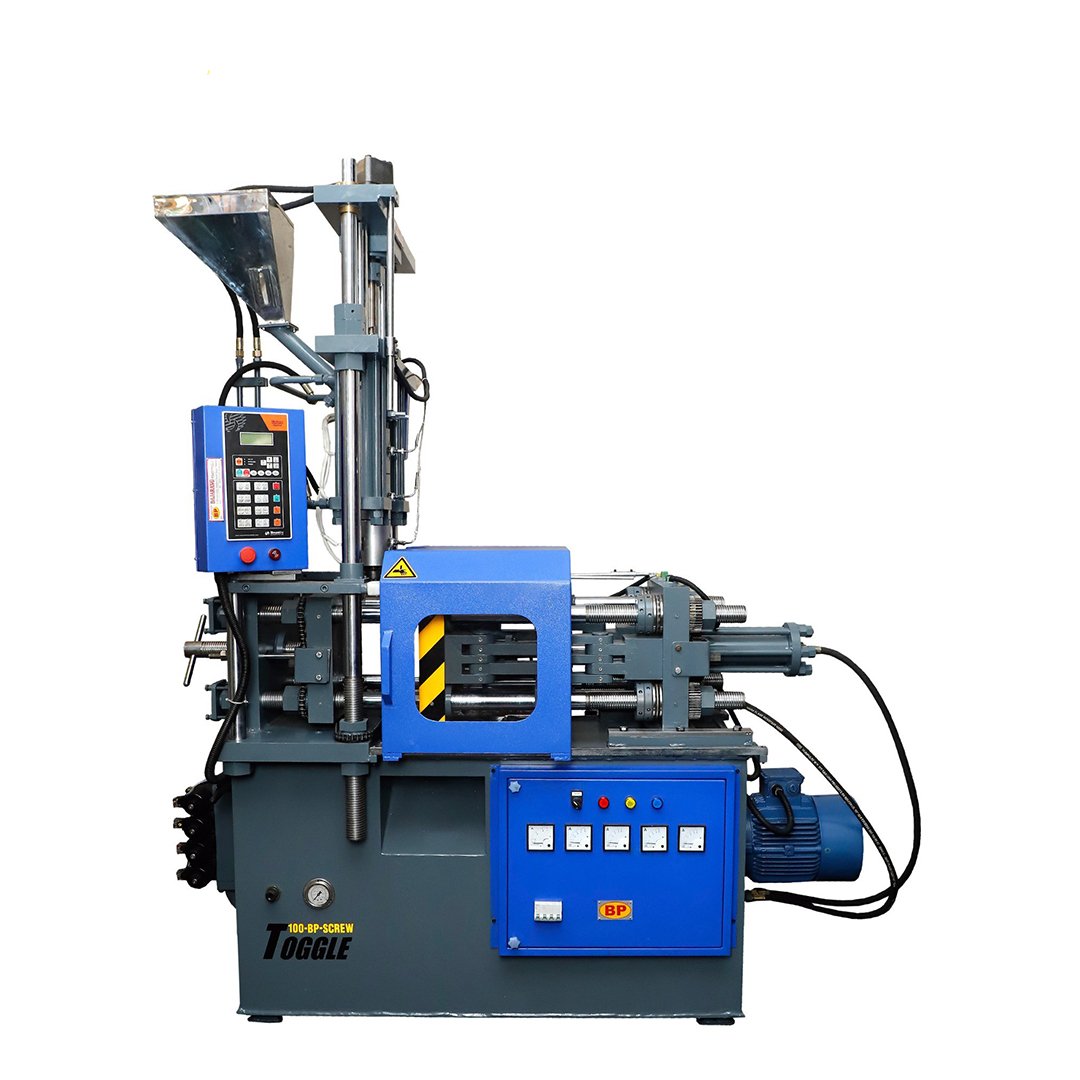

Cutting-Edge Technology

At the forefront of technology, our advanced facilities boast state-of-the-art machinery tailored for diverse manufacturing needs. From intricate leather craftsmanship to precision injection moulding, we guarantee efficiency.

| Sr. No. | Machine Type | Capacity (Kg/Hr) | No. of Machine | Machine Make/Model | Yr of Purchase | End Product/s |

|---|---|---|---|---|---|---|

| 1 | Automatic Injection Molding Machine | 4.0 Kg/Hr | 1 | Haitian | 2006 | Industrial |

| 2 | Automatic Vertical Injection Molding Machine | 1.5 Kg/Hr | 1 | Multiplas | 2018 | Industrial |

| 3 | Automatic Injection Molding Machine | 2.0 Kg/Hr | 1 | NesPack | 2017 | Industrial |

| 4 | Automatic Injection Molding Machine | 4.0 Kg/Hr | 1 | Yizumi | 2020 | Industrial |

At Harmony International, we excel in injection molding, crafting precision-engineered products for diverse industries. With a focus on innovation and precision, our solutions are tailored to meet specific industry requirements. By aligning our manufacturing capabilities with sector demands, we ensure versatile and customized solutions that drive success for our clients.

At Harmony International, our capabilities extend beyond standard components. We excel in:

Innovative Product Design:

- Bringing ideas to life through comprehensive product design services.

Advanced Prototyping with 3D Printing:

- Precision prototyping for validation using cutting-edge 3D printing technology.

Mold Design and Fabrication:

- Expertise in the design and fabrication of molds tailored to your specifications.

- Poly Polypropylene Co Polymer Natural ( Reliance C080MA, Exxon Mobil 7033)

- Nylon 6 Natural. (Gujlon M28NC, Domomid NC 6)

- Poly Oxy Methylene ( POM CO-Poly Kapital F20)

- Poly carbonate Clear ( Lexan 144R)

- Poly Propylene 20% Talc Filled

- Poly Carbonate 30% Glass Filled Flame Retarded (Lexan 243 R)

- Poly Carbonate 30% Glass Filled.

- Nylon 66 30% Glass Filled Flame Retarded.( Zytel 70G30HSLR)

- Nylon 66 Black ( Zytel 101L)

Build Your Own

Frequently Asked Questions

Our injection moulding processes utilize a variety of materials, including thermoplastics, thermosetting polymers, and elastomers. The specific material chosen depends on the requirements of the project, such as strength, flexibility, and durability.

We cater to a diverse range of industries, including automotive, electronics, medical devices, consumer goods, and more. Our expertise in injection moulding allows us to deliver solutions tailored to the unique needs of each sector.

Quality and precision are paramount in our injection moulding processes. We employ advanced machinery, rigorous quality control measures, and a team of skilled technicians to ensure that each part meets the highest standards of accuracy and consistency.

Yes, our state-of-the-art facilities and scalable production capabilities enable us to accommodate both small and large-scale orders. Whether you require a few prototypes or high-volume production, we have the capacity to meet your needs efficiently.

Our team adopts a collaborative approach to design and development, working closely with clients to understand their requirements and objectives. We utilize advanced design software and prototyping techniques to refine concepts, optimize designs for manufacturability, and ensure the successful execution of each project.